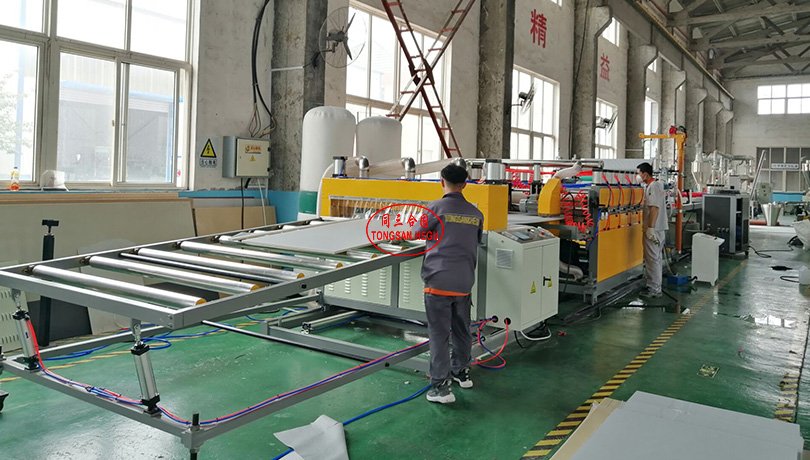

This PVC WPC skinning foam board extrusion machine can continuously and steadily produce PVC WPC foam board. The PVC WPC foam board has the advantages of fireproof, waterproof, anticaustic, moistureproof, mothproof, mildewproof and environmentally friendly, etc. The PVC WPC foam board is widely used in interior decoration, precast exterior wall panels, furniture making, bathroom decoration, poster board, partition, etc.

Inquire now

Add to cart

PVC WPC Skinning Foam Board Extrusion Machine

The conical twin-screw extruder has stable performance, which can make the melt plasticize well at a lower temperature. The cast aluminum heater is installed on the cylinder, which has high thermal efficiency, fast and uniform temperature rise, and is equipped with cooling fan.

1. Die head with streamlined runner surface, two half mold body design, die head disassembly, easy to clean.

2. Manual fine tuning of elastic die lip or movable upper die lip design, extrusion thickness 0.2-1.22mm. Special for lace

products and can be adjusted according to the thickness of products.

3. To adapt to the melt flow of different viscosity to get uniform distribution.

4. Die body adopts die steel or imported alloy steel to prolong the life of the die.

5. All the surface of the runner is plated with hard chromium, the average thickness is 25μm~50μm, and mirror polished. 6. Die head fasteners with high strength bolts of class 12.9.

7. The heating element adopts durable stainless steel heating rod and heating ring

Calibration Forming Machine:Number of set boards: four pairs. Width of shaping board: 1500mm Finalize plate closure: cylinder drive, independent up and down control Plate cooling: water cooling, optimize the design of flow channel Longitudinal movement of setting machine: 0.75 kW reducer motor drive

Haul-off machine:Rubber roller material: polyurethane adhesive Clamping mode: each pair of rollers is pressed by independent cylinder Drive: reducer motor Motor power: 5.5KW, 2 sets synchronous traction Control: Swiss ABB frequency converter