-

Home>

-

Products>

-

Auxiliary equipment>

We work togetehr with customers for the whole PP hollow corrugated sheet box making project from the sheet extrusion to the final box, the auxuliary machines for box making,such as automatic /semi-automatic die cutting machine, single/multi color printing machine, edge and corner welding machine.

Inquire now

Add to cart

Tongsanhegu have all series high quality PP hollow corrugated sheet machine ,the width of the products is 1220--3150mm, and the thickness is 1mm-12mm.The extrusion line can reach 2-10m/min, the high capacity at 200-600kg/h. And we provide high out production line with professional technology support,and auxiliary machine for package box making machines,such as the printing machine, die cutting machine, welding machine.

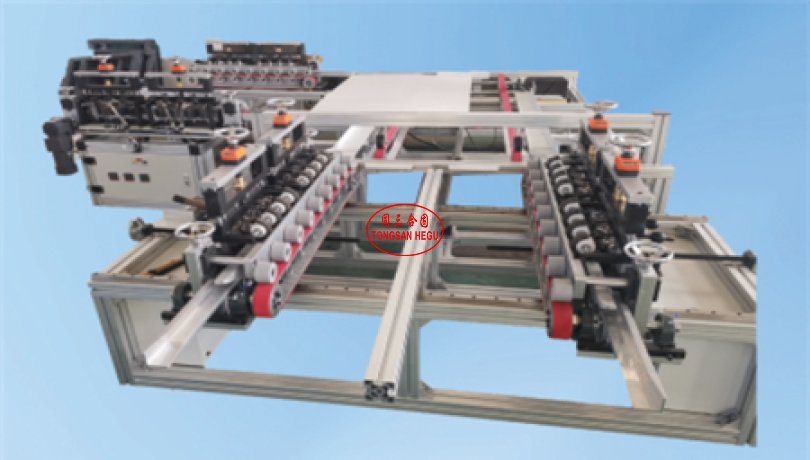

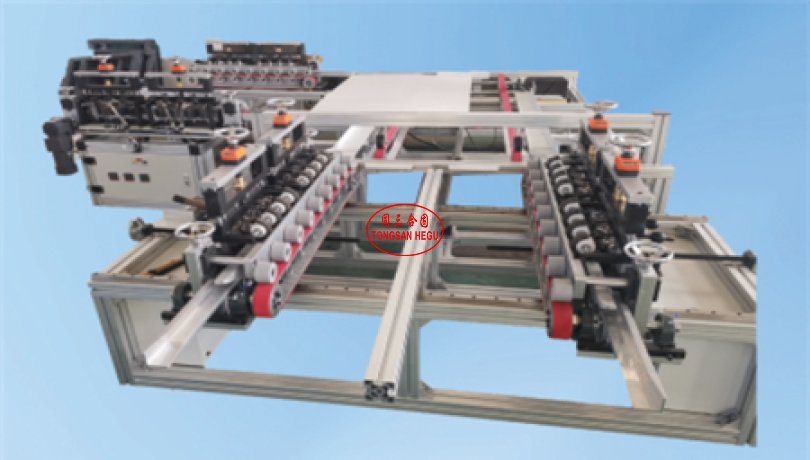

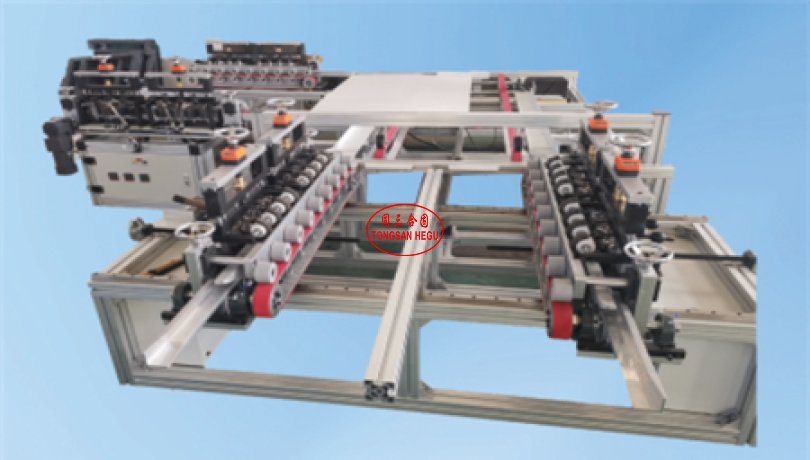

1, Automatic die cutting machine for packing box making

Equipment Description

•Equipped with high-precision gearbox, fast speed, long life, safe and reliable

•The front edge paper feeding adopts high-precision suction box to achieve smooth paper feeding under high-speed conditions.

•The newly designed tooth row system and reinforced chain can effectively improve the stability of paper operation, reduce maintenance and extend the service life of the machine.

•The pneumatic locking system of the die-cutting frame is convenient for operation. The die-cutting frame adopts an integrated structure, which is accurate and durable.

•The die-cutting pressure is uniform, the plate is less refilled, and the operation is visually designed.

•The automatic paper collection device is equipped with a down-blowing and flat-blowing system, which can perfectly collect paper under high-speed operation of the machine.

•The electronic control system adopts PLC control and is equipped with various safety protection devices. In case of failure, sound and light alarms and automatic shutdown are issued, which truly achieves human-machine safety.

•Equipped with automatic paper collection device with automatic counting device.

The binding machine is used for seaming the PP hollow sheet into packing box

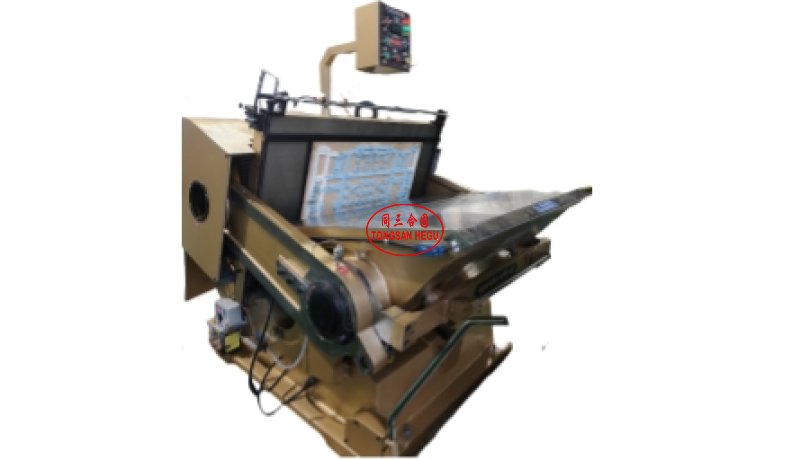

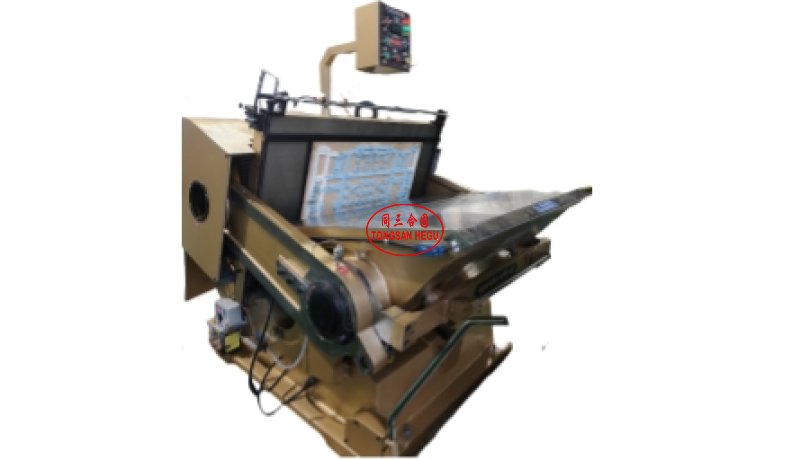

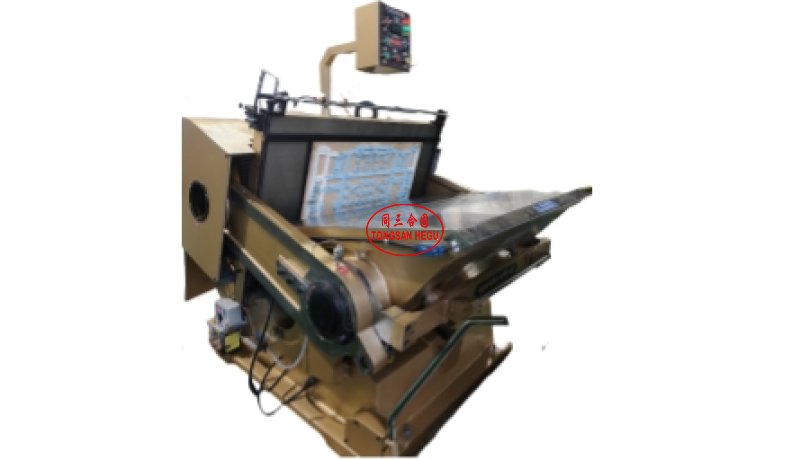

2,Semi-automatic die cutting machine for packing box

Imprinting plate format: 1020×550mm

Maximum hot stamping format: 950×550mm

Hot stamping speed: 1650 times/hour

Number of jump steps: 0-99 times (one set)

Stepping stroke: 0-550mm

Maximum electric heating power: 6KW

Motor power: 2.8KW

Machine net weight: 2500Kg

Dimensions (length×width×height): 1800×1550×1700mm

The creasing and cutting machine is used to emboss convex and concave trademarks on paper and plastic of different specifications, and can also cut paper boxes and other printed products. It is a supporting equipment for various types of double-sided printing machines, one machine for multiple uses, economical and affordable.

The machine has advanced and reasonable structure, stable performance, simple operation, etc. Its biggest advantages: high layout pressure, not easy to damage the machine parts, electroplated aluminum jump step is computer controlled, with a large range, which speeds up the work efficiency and is deeply loved by the majority of users.

3,Multi-color printing machine

Functions and features of the whole machine:

The whole machine is designed strictly in accordance with the EU CE safety standards, with standardization, universalization and humanization. Based on the concept of human-machine integration manufacturing, it can be set, corrected, executed, replaced, and memorized directly on the touch screen. It is a product with super cost-effectiveness.

Touch screen human-machine interface and electric control dual system operation function, with intelligent zeroing, one-key order adjustment, automatic version, memory automatic reset, storage order and other functions;

The whole machine wall panels and important parts are all treated with aging, tempered to eliminate metal internal stress; they are all made by high-precision machining center and grinded by CNC grinder.

The whole machine shaft and roller are made of high-quality steel, ground, high-precision computer dynamic balance correction, and hard chrome plated on the surface.

The whole machine transmission gears are all made of 40Cr alloy steel, carburized and quenched, with a hardness of HRC58~62; after grinding, 6-level precision, to ensure high color registration accuracy for long-term use.

The transmission parts of the whole machine (shaft and gear connection) are all keyless connection (expansion sleeve) to eliminate the connection gap, which is suitable for long-term high-speed operation with large torque.

The transmission bearings and important transmission parts of the whole machine are all well-known brands: Harbin brand, which is easy to maintain and has a longer service life.

The lubrication system of the whole machine adopts spray-type automatic lubrication and is equipped with an automatic balancing device to keep the oil of each unit at the same level.

The whole machine has a preset adjustment function, automatic zeroing for paper feeding, printing, and die-cutting, one-button adjustment, automatic version alignment, and automatic memory reset.

The working gap adjustment of the whole machine adopts PLC electric and touch screen adjustment, which is fast, accurate and convenient to execute.

The whole machine adopts frequency conversion control, which makes the startup operation smoother and more energy-saving. The phase adjustment adopts frequency conversion control, which can be adjusted during shutdown and operation (PLC touch screen operation).

The whole machine is equipped with the function of storing orders, which can store 999 orders. According to the size of the carton, set the parameters of each unit on the touch screen, store the order and give it a number. When producing the order again, search for the order number and use it, making order change more convenient and faster.

The whole machine is equipped with the function of automatic inking by the extrusion force of the rubber shaft. The PLC touch screen turns on the ink uniformity function and manually adjusts the pressure between the rubber shaft and the anilox roller. The machine will automatically ink when the photoelectric sensor detects that the pressure between the rubber shaft and the anilox roller is appropriate, preventing the ink from flowing directly to the printing plate roller and contaminating the printing plate roller due to the pressure between the rubber shaft and the anilox roller being too low.

4, Single color screen printing machine

Widely used in the packaging industry

(e.g. Cigarette box packaging, wine box packaging, gift box packaging, etc.

Card printing), trademark, calendar, oil painting, computer keyboard,

Printing of New Year pictures, transfer paper, adhesive and credit CARDS;

Also suitable for electronic industry related printing.

Equipment model | JY-7010B |

Working platform area(mm) | 800*1100 |

Maximum printing area(mm) | 700*1000 |

Largest screen setup (mm) | 950*1200 |

Minimum screen setup (mm) | 800*950 |

Load bearing thickness(mm) | 0-20.0-50 |

Printing speed(pcs/h) | 500-1200 |

Power (kw) | 2.3 |

)Minimum height of workbench plate (relative ground)(mm) | 820 |

Shape size (l*w*h)(mm) | 1900*1450*1280 |

Nominal voltage(v/Hz) | 220V50HZ / 380V |

5, PP hollow sheet edge and corner welding machine

6, PP hollow corrugated sheet box welding machine

The binding machine is used for seaming the PP hollow sheet into packing box

Item | parameter |

Machinery speed(Nail/min) | 350 |

Power(kw) | 0.37 |

Finalize the design | 180 |

Nail wire type | 17# 18# |

Nail type | Single diagonal nail, double diagonal nail |

Shape size | 1560*500*1880 |

Weight | 430kg |