-

Home>

-

Products>

-

Auxiliary equipment>

We have different model winder machines suitable for plastic pipes and sheets, and it can customized according the requirements.

Inquire now

Add to cart

1, Automatic winding machine with online packing and Unloading

Automatic coiling machine, model WA8-B

1. Automatic coiling and cutting of corrugated tubes

2. Automatic coiling, cutting and bundling functions, single-station coiling

3. Independent servo motors are used for coiling and winding drives, controlled by digital programming

4. Friendly human-machine interface

5. Cutting and clamping are completed automatically, avoiding time waste and possible operational errors in caching and rewinding

6. Integrated automatic unloading and bundling

Applicable pipe diameter | 22-36mm o.d | Reeling drive | 1kw |

Maximum line speed | 40m/min | Cable drive | 0.2kw |

| Maximum weight of coil | 30kg | Maximum outer diameter | 1100mm |

Fixed inner diameter | 430mm | Adjustable width | 200-250mm |

Maximum dept | 335mm | Automatic unloading device | Automatic packing device |

2,Double position winder for single wall corrugated pipe/ small PE pipe/ Soft PVC profiles

| Type | Double station coiling winding device |

Alignment mod | Adopt rolling ring traverse |

Coiling spee | 0-35m/min,According to the pipe speed ,can be adjusted |

| Driving moving blad | 0.75kw |

| Control of reeling device | Pneumatic |

Dimension of coiling disk | 280*720*350mm |

Windth of coiling paddle | 180-350mm can be adjusted |

Counting mod | Inductive counting device ,alarming when the pipe coiling disk is full |

3,Single position winder for 16-125mm PE pipes

Single station pipe diameter: 16-63mm,

Core diameter: 1000-1500mm,

Width: 250-350mm,

Maximum outer diameter: 1500mm

Line speed: 15M/min,

Motor power: 30N

Single station pipe diameter: 75-125m m,

m,

Core diameter: 1500-2500mm,

Width: 350-500mm,

Maximum outer diameter: 3500mm

Line speed: 6M/min,

Motor power: 30N

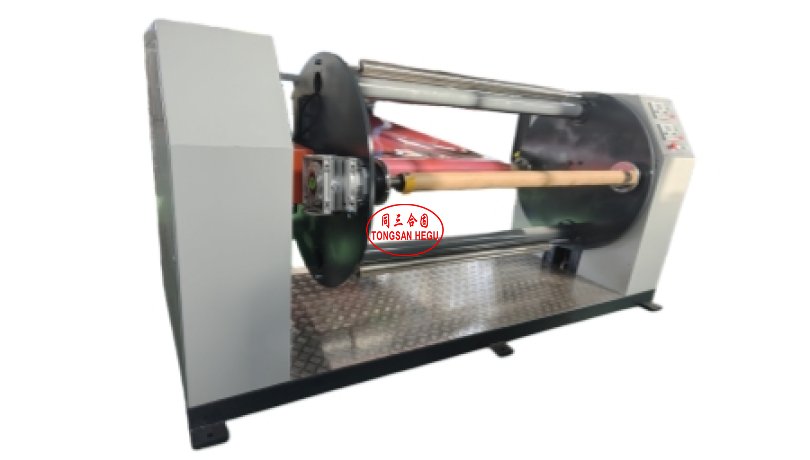

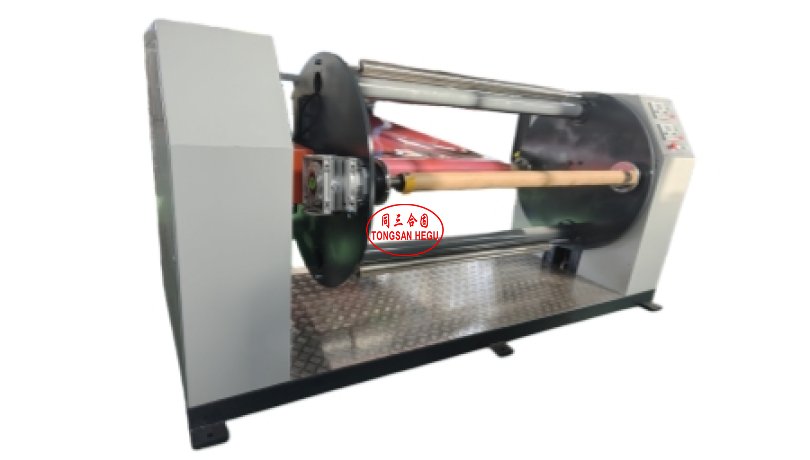

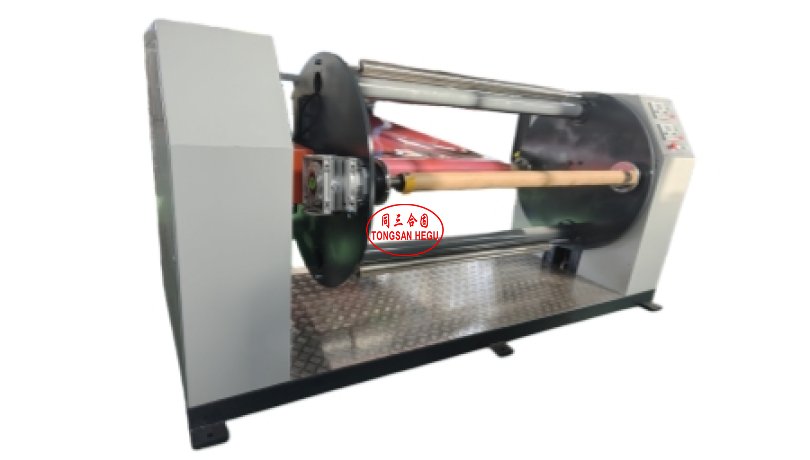

4, Coiling machine for plastic sheet

1. The tightness of the sheet can be adjusted by the swing roller to make it better for winding.

2. Floating mechanism, compact structure, smooth movement, easy manual operation.

3. The installation position of the tension detector is more reasonable, which improves the control accuracy.

4. Maintenance-free rolling device, smooth rolling, accurate positioning, limited manufacturing cost and maintenance cost.

5. Double pressure roller flying knife device, compact structure, no need to wrap tape on the surface of the core,

the cut film end can be quickly and automatically attached to the core, reducing the manufacturing cost, and the economy is obvious.