PP/PE Plastic Sheet/Plate Extrusion machine

This line is specialized for making PP PE plastic sheet/plate. Consists of high effective extruder, T-die head, three roller calender, cooling frame,haul off machine,cutting machine and stacker.

This machine suitable for making PP/PE sheet/plate which width less than 3000mm, thickness from 0.5mm to 20mm.

Inquire now

Add to cart

PP Sheet

PP sheet and board have good health properties,low density,good corrosion resistance and high heat resistance, temperature characteristics. Is currently green products.It can be widely used in the chemical industry,food industry,antiseptic industry,clean industry,environmental protection equipment manufacturing industry.

PE Sheet

PE sheet and board are widely used in luggage lining,garment collar lining,pad and building decoration materials and water treatment engineering materials,etc.

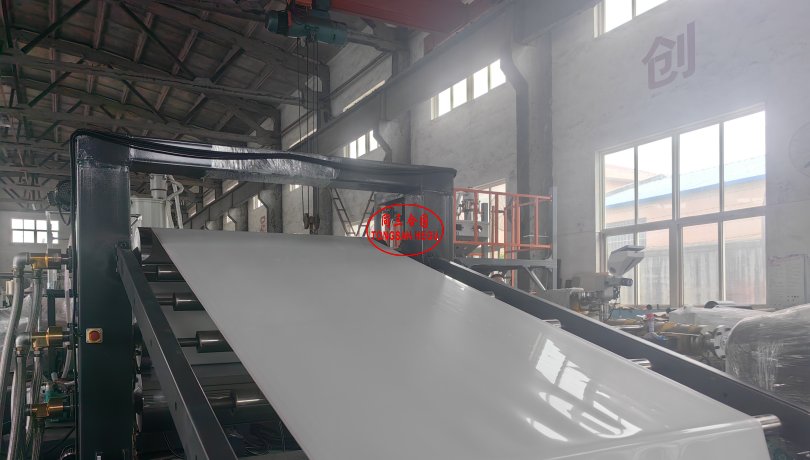

Plastic sheet extrusion line is capable of continuously producing mono-layer or multi-layer PP PE plate and sheet with the width less than 3000mm and thickness of 0.5-20mm .

| Machine model | TS-1200 | TS-1600 | TS-2000 |

| Extruder model | LSJ-90/33 LSJ-120/33 | LSJ-120/33 LSJ-130/33 | LSJ-120/33 LSJ-130/33 |

| Sheet width | 1200mm | 1600mm | 2000mm |

| Sheet thickness | 1-8mm;3-16mm | 1-8mm;3-16mm | 1-8mm;3-16mm |

Detailed Machine Pictures:

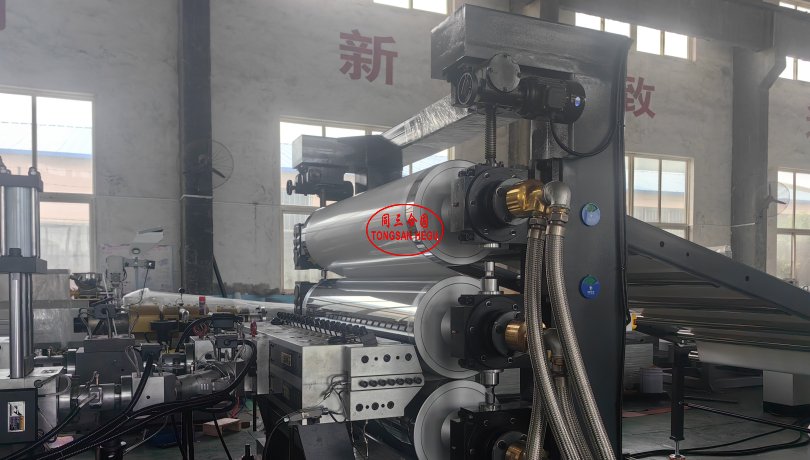

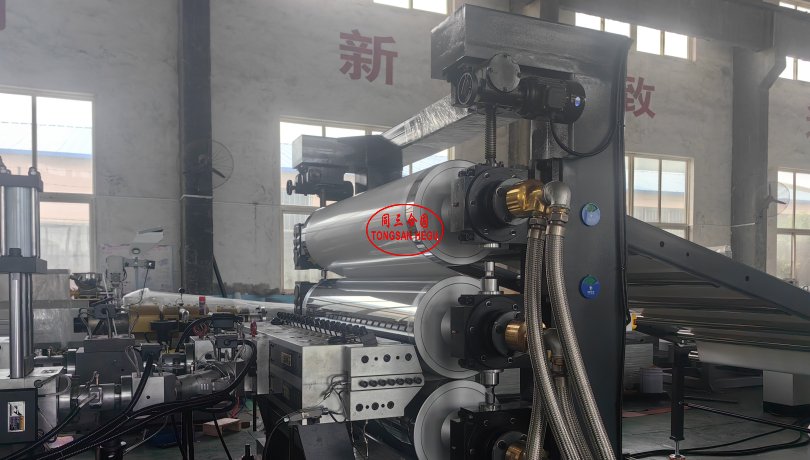

(1)Extruder for Plastic sheet extrusion machine

Appropriate single-screw extruder (exhaust or not) should be chosen on the basis of different materials. Specially designed screw and advanced temperature controlling system ensure the good plasticization, high output and stable extruding.The customer can choose to make single extrusion or co-extrusion sheet or plate.

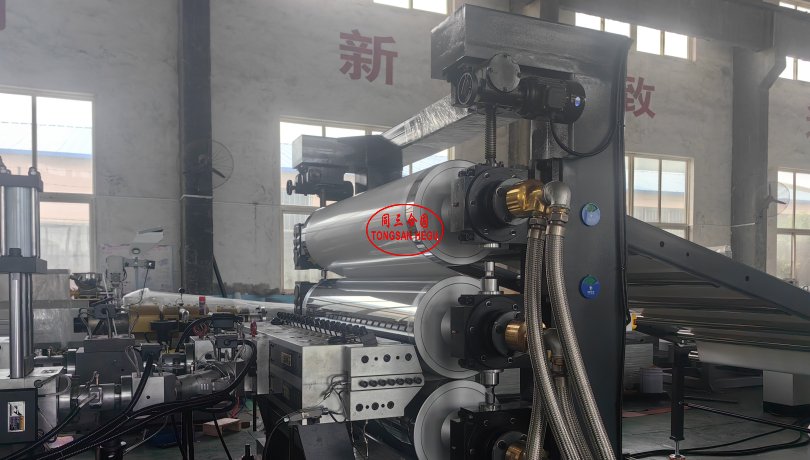

(2)Mold for Plastic sheet extrusion machine

The quick screen changer of hydraulic system ensures the short course of screen changing without material-leakage. Reasonable structure of mould should be chosen in terms of material, whereas moulds of clothes-rack mode are widely accepted to regulate flow-distribution and guarantee even thickness of plates (sheets).

(3)Three roller calendaring machine for Plastic sheet extrusion machine

Inclined and vertical three-roller calendaring machine should be chosen according to the thickness of the plates(sheets). Temperature controller operates separately and gap among the three rollers can be adjusted freely, and the central roller has special design of regulating angle. Both ensure the excellent calendaring effect and even thickness of plates (sheets).

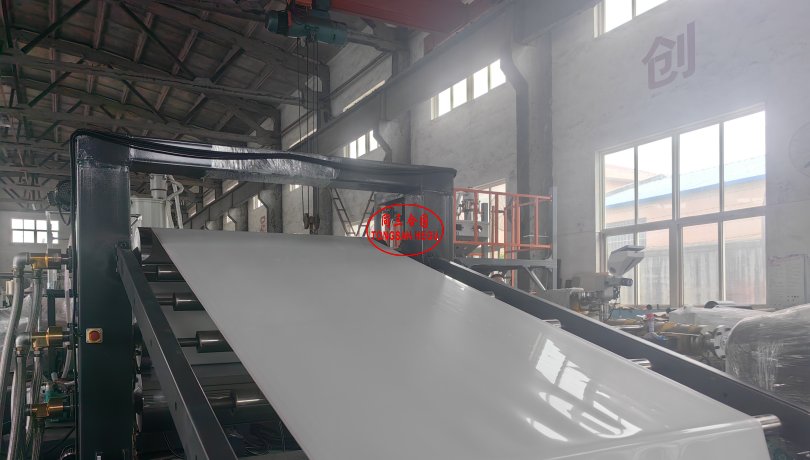

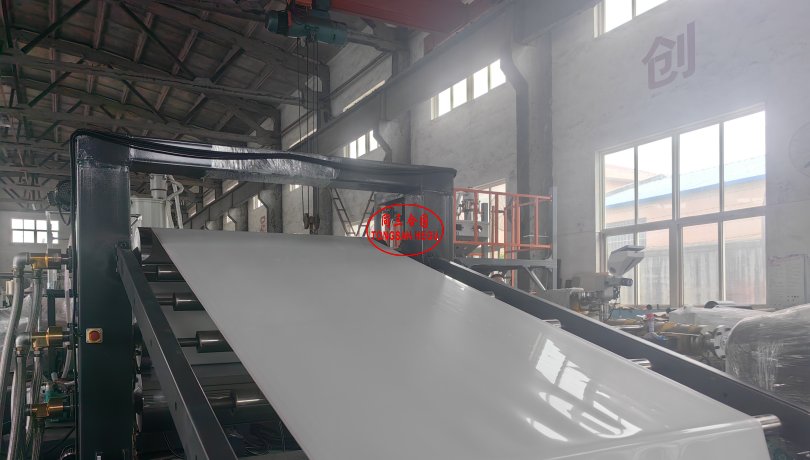

(4)Cooling bracket for Plastic sheet extrusion machine

Equipped with corresponding guide roller, the cooling effect is better. In addition, the edge-shearing device equipped can guarantee fixed width of plates (sheets) and quality of edge

(6)Haul off machine for plastic sheet extrusion machine

Double roller haul off machine

Roller material: rubber

roller up and down: by cylinder control

Speed control: Frequency

7,Cutting machine for Plastic sheet extrusion machine

It is of length-fixed cutting with cutting precision less than 2mm and adopts alloy blade or rigid alloy saw bit to ensure the good cutting effect and constantly stable performance

(8)Plastic sheet winding machine or stacker The customer can choose use winding machine to make the sheet to a roll or cut the sheet piece by piece.

(8)Plastic sheet winding machine or stacker The customer can choose use winding machine to make the sheet to a roll or cut the sheet piece by piece.